crushed ore then loaded on to a conveyor bel

Crushed ore is then loaded on to a conveyor belt which will take it for the storage bin. ... crushed ore is then loaded on to a conveyor bel 9.7 (Total: 10) ... Get Quote . Crushing and conveying – Waihi Gold. At the Martha Mine rock is crushed and then transported from the open ... (the overland conveyor) transports the ore from the ... the material can also be loaded ... Get Quote. More ...

crushed ore then loaded on to a conveyor bel

crushed ore conveyor beltorchardfarmtoppers. crushed ore is then loaded to a conveyor belt that can take it for the storage bin side the storage bin ball mills and other grinding machine grind the ore …

Crushed Ore Is Then Loaded On To A Conveyor Bel

Crushed Ore Is Then Loaded On To A Conveyor Bel. Iron ore benefication process 1rge raw iron ore for primary crushing are fed into the jaw crusher by plate feeder and are reduced to 8 inches or smallerfter first crushing, the material will transferred to cone crusher by belt conveyor for secondary crushing the crushed iron ore stone will then transferred to vibrating screen for.

THE MINING PROCESS | LOMATI MINE

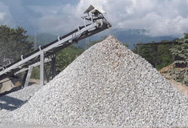

The crushed ore is then dropped onto a conveyor belt. The belt transports the crushed ore along the conveyer where cement is added to mix it with dry ore. The conveyor belt takes the crushed ore peppered with cement to a High Frequency Vibrating Screen. This screen is used to separate the oversize ore from the fines before the crushed ore proceeds to the Agglomerator.

Crushed Ore Conveyor Belt - mine-equipments.com

Then crushed copper is loaded on to a conveyor belt which takes it to the storage bin ... The analyzer, installed above the conveyor belt with crushed ore or other material, transfers data on the composition of the material in real-time to the ... Iron Ore Processing for the Blast Furnace heavy-duty conveyors. ... The crushed material is transferred by belt... belts continuously feed the ore ...

Crushing and conveying – Waihi Gold

Material is loaded into the crusher bins (1) by trucks or loaders.The material travels along a conveyor underneath the rotating drum (2). The picks fracture any material that is larger than the gap between the drum and the belt. An electomagnet (3) removes tramp steel from the old workings. The material is transported (4) to the main overland ...

The Process - Kaunisiron

The ore is loaded onto mine trucks using large wheel loaders for further transport to the primary crusher. Primary crusher The primary crusher is about 30 metres high and can manage diameters up to 90 cm. once the ore has been crushed to the right dimension, it continues on an encapsulated belt conveyor making the 1 km transfer to the screening plant.

Conveyor Belt - an overview | ScienceDirect Topics

A long horizontal conveyor belt is used to transport granular iron ore. The ore, initially at rest, is fed gently on to the moving rubber-covered belt at one end, covering its whole width, and falls off at the other.

Major Mines & Projects | Big Gossan Mine

05.03.2020 · Big Gossan Mine (Grasberg Complex) ... Trucks are chute loaded and transport the ore to a jaw crusher. The crushed ore is then hoisted vertically via a two-skip production shaft to a level where it is loaded onto a conveyor belt. The belt carries the ore to one of the main underground conveyors where the ore is transferred and conveyed to the surface stockpiles for processing. The Big Gossan ...

Review of the in-pit crushing and conveying …

Review of the in-pit crushing and conveying (IPCC) system and its case study in copper industry . Conference stone (PDF Available) · October 2011 with 5,805 Reads How we measure reads A read ...

Conveyor Belt Overloading - YouTube

26.04.2015 · Poor loading control at the loading area of this belt causes spillage due to overloading. This in turn is then cleaned by employees who fill the belt to the ...

Crushing Dirty Brass and Copper in a Hammer …

14.05.2019 · It then falls onto a conveyor belt which carries the product under a cross belt magnet where the ferrous and magnetics are removed. The final product can then …

The World’s Most Powerful Belt Conveyor System …

Our world-leading belt conveyor system transports crushed copper from underground storage bins to the surface along a 7 km underground tunnel that overcomes a non-insignificant 1 km of vertical elevation change. Once on the surface, ore is then fed onto an overland conveyor that transports it the final 6 km to the distribution silo. The underground system (comprising two conveyors of about ...

Secondary Crushed Ore Bin Distribution Conveyor

Secondary Crushed Ore Bin Distribution Conveyor Prompt : Caesar is a famous mining equipment manufacturer well-known both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc.

September | 2012 | Crusher Manufacturers In The …

Crushed ore is then loaded on to a conveyor belt which takes it to the storage bin. In the storage bin, ball mills and other grinding machine grind the ore until it is a fine powder. During the crushing process, liming has improved the capacity and end crushing products with our secondary crusher and tertiary crusher. The total energy consumption is reduced considerably.

Iron Ore Processing for the Blast Furnace

More than 6,000 tons of taconite can be crushed in one hour. The crushed material is transferred by belt to an ore storage building, which holds up to 220,000 tons of taconite. An apron feeder sends the ore to the concentrator building for grinding, separating, and concentrating. Concentrating The crude taconite is now roughly the size of a football or smaller. A series of conveyor belts ...

First Ore Milestone at the World’s Most Powerful …

Our world-leading belt conveyor system transports crushed copper from underground storage bins to the surface along a 7 km underground tunnel that overcomes a non-insignificant 1 km of vertical elevation change. Once on the surface, ore is then fed onto an overland conveyor that transports it the final 6 km to the distribution silo.

Welcome to - Boliden

000 tonnes of ore are crushed. The crushed ore is transported by conveyor belts through an . intermediate stockpile and then to the ore storage located by the concentrator. The conveyor. There are seven conveyors with a total length of 7 km for the . transportation of ore from the crusher to the ore …